With years of experience with numerous CMM software packages and specialized fitting software, Axymetrix was built on GD&T inspection with 3D coordinate metrology systems. This is enhanced by standards committee experience in GD&T, mathematical definitions, CMM technology, and measurement data reporting.

Axymetrix is a strong proponent of using 3D coordinate metrology to support dimensional engineering activities. Data from CMMs, measurement arms, laser trackers, and scanners contain a wealth of extra information that is often untapped. Axymetrix offers a variety of services to extract additional value from 3D measurement data.

GD&T Inspection: Get a full dimensional FAI report generated quickly from your CAD model and raw XYZ point data:

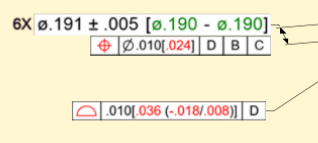

- All standard-compliant geometric tolerance and datum feature types are supported, no matter how complex.

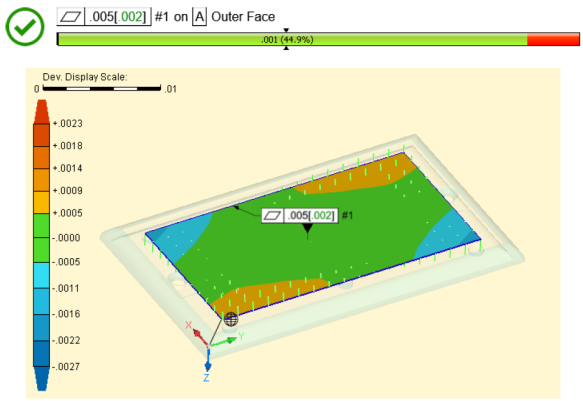

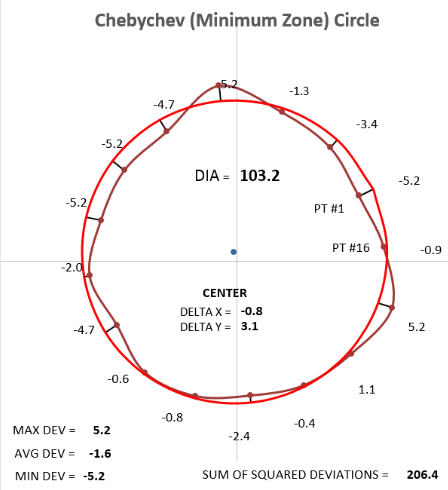

- Reporting formats include numerical measured values for each characteristic and graphical views showing the deviations.

- Ideal for the first article inspection, where all characteristics on the drawing must be shown to be in conformance

GD&T Metrology Software: Axymetrix can help you get the most out of your investment in 3D coordinate metrology systems and software:

- Guidance on how to use your software to inspect GD&T properly

- How to select the correct analysis algorithms for different situations

- Avoid common software pitfalls that can ruin measurement accuracy even with mechanically accurate equipment

- How to define coordinate systems and datum reference frames

- How to distribute the measured points for maximum effectiveness

- Maximize your software’s GD&T functionality and identify any limitations

Inspection Report Review: Output from coordinate metrology systems can be difficult to interpret. Axymetrix can help make sense of the dimensional reports and ensure that the characteristics have been interpreted and inspected correctly.

Dimensional Root Cause Analysis: When parts don’t conform to the GD&T specifications, many different root causes are possible. Axymetrix has an extensive set of tools to diagnose and fix dimensional problems from many different sources:

- Problems with the parts – using 3D metrology data and analysis tools to analyze the as-produced geometry and diagnose the root cause in the manufacturing process

- Problems with the inspection – using extensive knowledge of inspection equipment, CMM software programming techniques, and algorithm choices. Axymetrix can often show how erroneous results were reached and what needs to be corrected.

- Problems with the GD&T itself – sometimes, the GD&T doesn’t effectively capture the fit and function requirements of the part. Axymetrix has the depth of GD&T application experience and detailed knowledge of the standards to identify suboptimal GD&T specifications and propose alternatives.